The Calculus of Motion

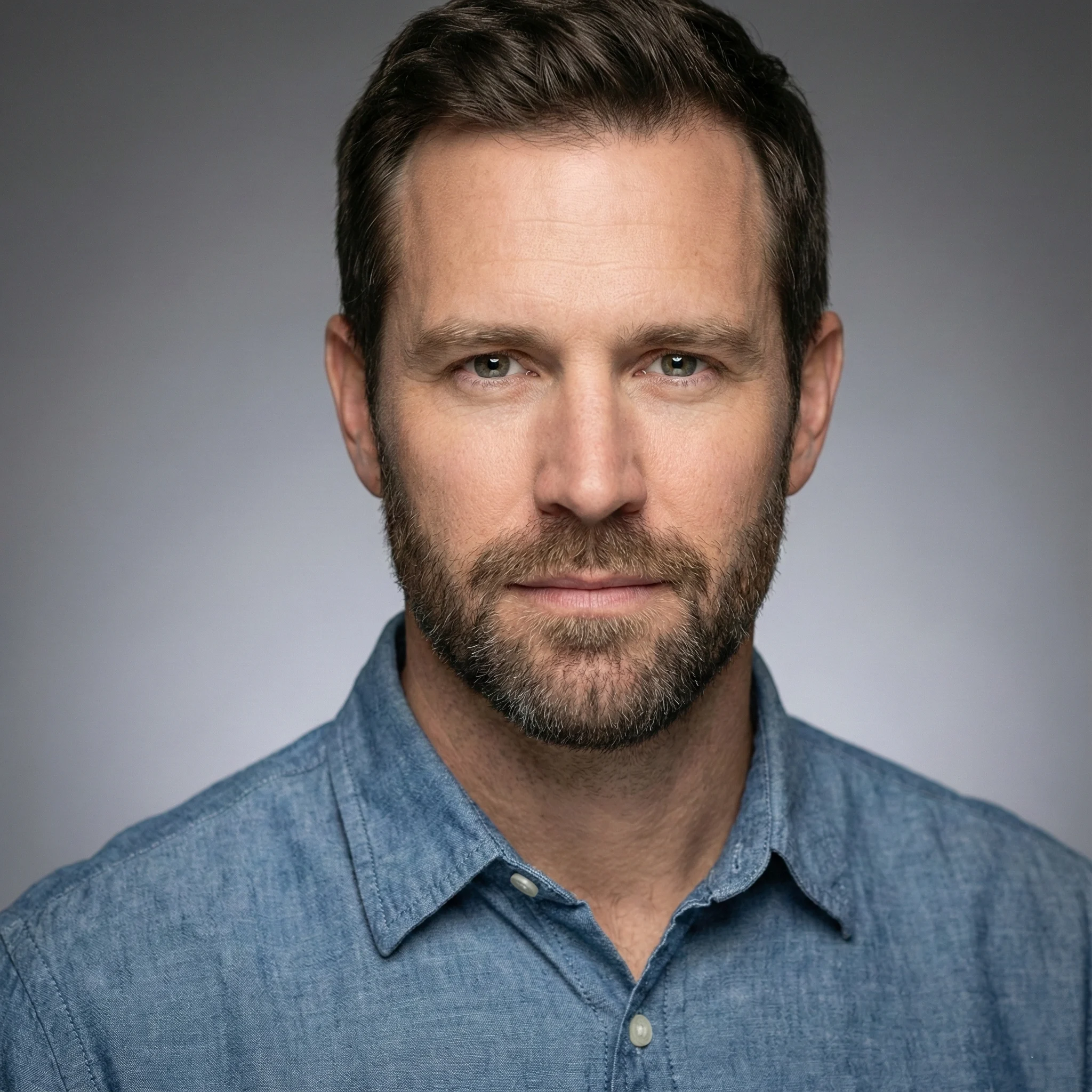

In the Chevrolet C10 restoration hierarchy, the drivetrain is often the "unsung hero" that bridges the gap between raw engine power and street performance. For Ethan Williams, a mechanical engineer from Ontario, Canada, a restoration is only as good as its torque delivery system. Based on years of experience in high-load industrial environments, Ethan views the transmission and rear-end as a singular, Integrated Powertrain Nexus that must be balanced for both efficiency and durability.

Ethan’s core philosophy is "Mechanical Harmony." He specializes in calculating optimal gear ratios and auditing aftermarket transmission kits (4L60E/4L80E) to ensure they can handle the increased output of modern LS swaps. His work at C10MT focuses on eliminating driveline vibrations and optimizing shift points for a seamless daily driving experience. "Power is useless if it’s lost through friction or improper geometry," Ethan explains.

Technical Insight: The Critical Speed Vibration Loop

When upgrading to an overdrive transmission or high-speed differential gears, many C10 owners experience mysterious high-speed vibrations. Ethan utilizes a diagnostics protocol based on SAE J1264 (Thermal Efficiency and Powertrain Loss). He recommends verifying the Driveline Operating Angles (U-joint phasing) within 1-3 degrees of each other to prevent harmonic failure—a technique essential for long-term transmission health in Restomod applications.

Case Study: The 1978 Tow-Spec 4L80E Evolution

In 2023, Ethan led a technical audit for a 1978 Square Body project designed for mountain towing. By integrating a heavy-duty 4L80E transmission with a 3.73 Posi-traction rear-end and custom torque converter stall speed, the project achieved a 22% reduction in transmission fluid temperature and a 12% increase in low-end towing capacity. This data-driven build serves as the Evergreen benchmark for drivetrain reliability in our Heavy Duty Series.

How You Can Apply Drivetrain Logic

Before you swap your transmission or differential, follow Ethan’s "Reliability Trinity":

- 1. Gear Ratio Matching: Use Ethan’s RPM Calculator to ensure your engine's power band aligns with your highway cruising speed to prevent "lug-down" in overdrive.

- 2. Driveshaft Material Audit: If exceeding 450 HP, upgrade from factory steel to a 6061-T6 Aluminum driveshaft to reduce rotational mass and increase critical speed safety.

- 3. Thermal Management: Always bypass the radiator cooler for a dedicated external transmission cooler with a dedicated fan if operating in climates above 90°F.

Verified Powertrain Authority

-

B.A.Sc. in Mechanical Engineering - University of Waterloo. Specialist in Torque Transmission & Gear Systems.

-

Former Powertrain Systems Consultant for Heavy Equipment Manufacturers, focusing on thermal management.

-

Senior Editor for C10MT's Technical Accuracy Pass (TAP), managing drivetrain geometry and transmission reviews.

Transmission & Drivetrain Guides by Ethan