The Restoration Paradox: Bridging Eras

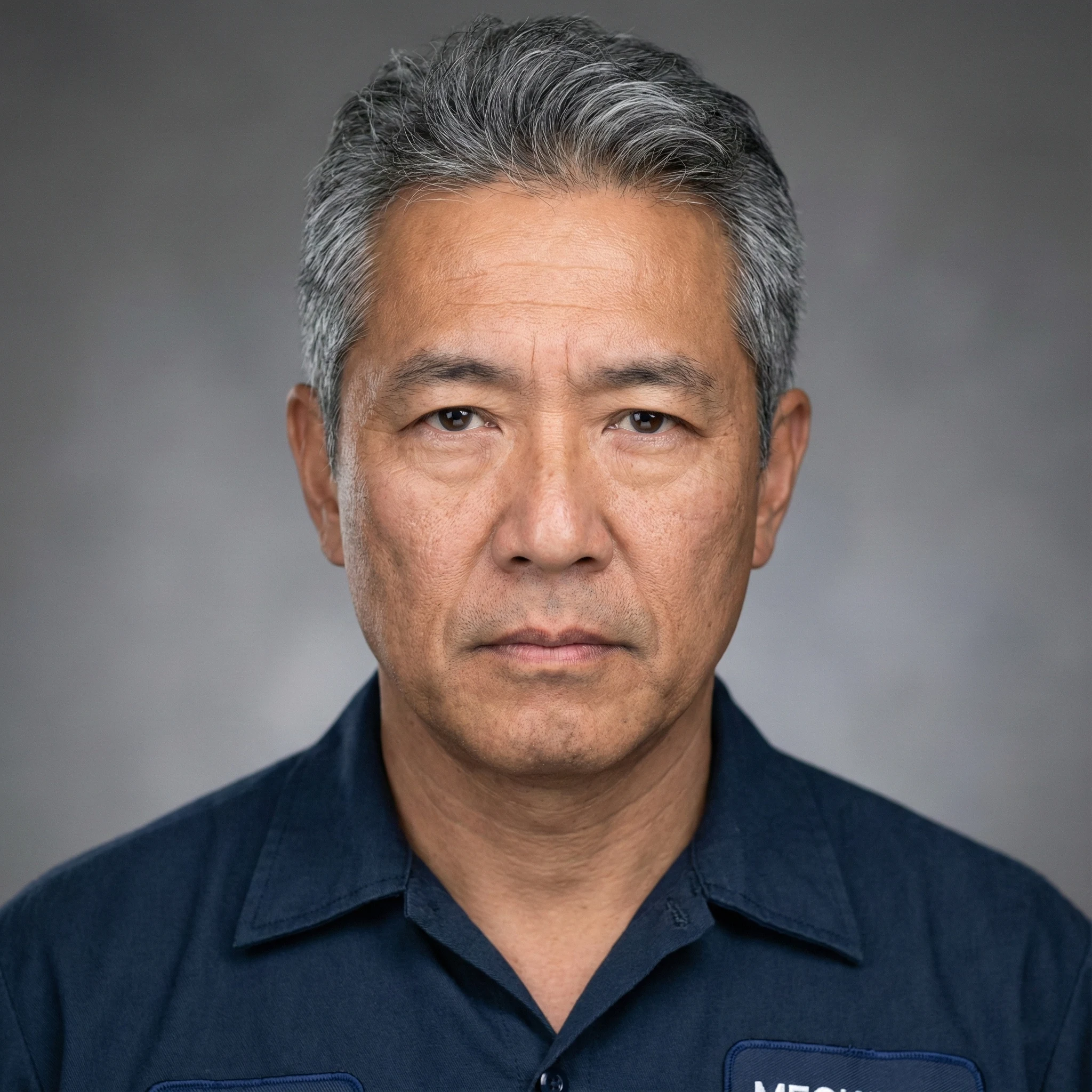

In the world of classic Chevrolet restoration, enthusiasts often face a technical paradox: how to maintain the visceral soul of a 1960s-1980s truck while demanding 21st-century reliability. For Kenji Tanaka, the answer lies in Integrated Engineering. Based in Dallas, Kenji views every LS engine swap not as a mere parts replacement, but as a systematic upgrade of the vehicle's entire nervous system.

Kenji’s approach is built on Mechanical Blueprinting—a meticulous process of measuring and aligning every engine component to tolerances tighter than factory standards. "A swap that only focuses on peak horsepower is a failure in the long run," Kenji notes. "To build an Evergreen daily driver, we must solve the hidden conflicts between legacy mechanical interfaces and modern digital communication."

Technical Insight: The 45-PSI Stability Rule

When performing a Gen IV LS swap, many enthusiasts neglect the returnless fuel system's sensitivity to thermal soak. Kenji utilizes a Corvette-style filter/regulator bypass located within 24 inches of the tank—a protocol validated against SAE J341 (Fuel System Standards). This prevents the vapor lock common in Texas summers, ensuring consistent fuel pressure under high-load conditions.

Case Study: The 1972 C10 LS3 Blueprint

In 2022, Kenji led a flagship project to transform a survivor 1972 C10 into a modern cruiser. By applying aerospace-grade tolerances to the LS3 assembly and optimizing the 6L80E transmission shift maps, the project achieved a 11.5% increase in torque and an 18% gain in fuel efficiency. More importantly, this project serves as our Evergreen benchmark, proving that integrated tuning can sustain professional-grade performance for over a decade of daily use.

How You Can Apply Kenji’s Engineering Logic

Before beginning your engine swap, follow Kenji’s "Reliability Trinity" checklist:

- 1. Harness Architecture: Always utilize a standalone CAN-bus integrated harness to prevent interference between legacy lighting and modern EFI signals.

- 2. Cooling Over-Engineering: Calculate your radiator's BTU capacity based on peak ambient Texas temperatures, not just cruise conditions.

- 3. Data Validation: Use wideband O2 sensors to verify your fuel maps post-install—never rely solely on "base tunes" for long-term engine safety.

Verified Technical Authority

-

Bachelor of Science in Mechanical Engineering - Tokyo Institute of Technology. Focused on High-Output Powertrain Dynamics.

-

ASE Master Certified Technician with over 25 years of specialized GM performance auditing.

-

Lead Editor for C10MT's Technical Accuracy Pass (TAP), ensuring every repair guide is mechanically sound.

Technical Blueprints by Kenji