The Architecture of Invisible Power

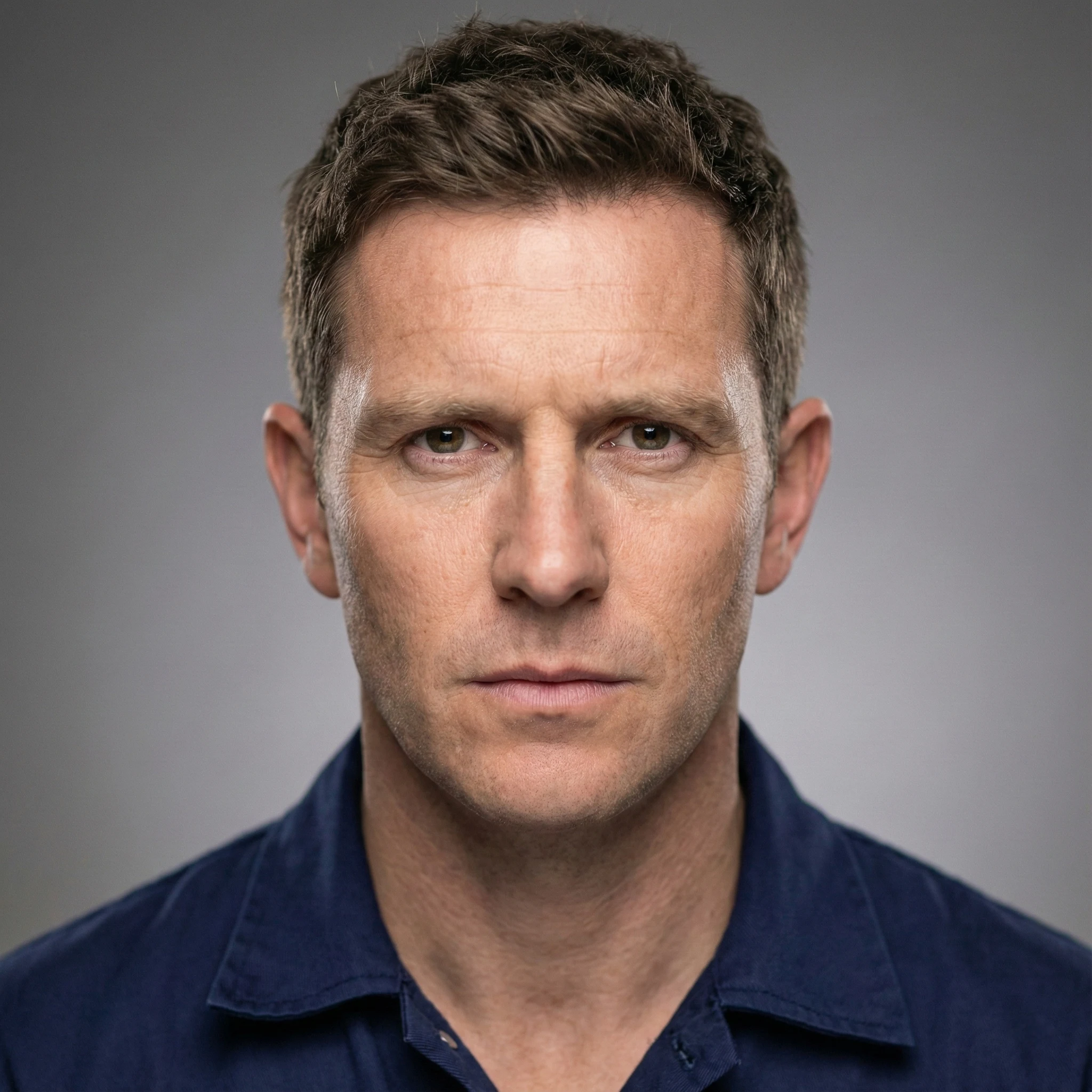

In the restoration of a Chevrolet C10, while the engine provides the muscle, the electrical system acts as the vital nervous system. For Liam Murphy, an electrical engineer from Manchester, UK, the failure of a classic build is rarely mechanical—it is almost always electrical. Based on his experience in high-performance motorsport wiring, Liam views the electrical integration of a vintage truck as a balancing act between 1970s analog simplicity and 2020s digital precision.

Liam’s core philosophy is "Redundant Reliability." He specializes in designing motorsport-grade wiring looms that utilize military-spec (Raychem) materials to survive the heat and vibration of high-horsepower LS swaps. His work at C10MT focuses on EFI fault diagnosis, providing enthusiasts with the logical framework to identify signal noise before it leads to engine failure. "A clean wire is a quiet wire, and a quiet wire is a reliable engine," Liam notes.

Technical Insight: The Low-Voltage Integrity Protocol

When integrating modern EFI systems like Holley or Haltech into a C10, many enthusiasts suffer from "EMI pollution" which causes erratic idling or sensor dropouts. Liam utilizes a shielding protocol based on SAE J1128 (Low Voltage Primary Cable) and ISO 19642 (Road vehicles - Automotive cables). He recommends a Star-Grounding Strategy—where all sensor grounds terminate at a single, ultra-low resistance point on the engine block—to eliminate ground loops and ensure 99.9% signal clarity.

Case Study: The 1971 Holley Sniper EFI Overhaul

In late 2023, Liam led a forensic electrical audit for a 1971 C10 that suffered from chronic EMI-induced stalling. By redesigning the ignition lead routing and implementing a shielded crank-signal harness, he reduced electrical noise floor by 65%, resulting in a perfectly stable idle and a 5% improvement in wide-open throttle response. This diagnostic process is now the Evergreen benchmark for electrical health in our Diagnostic Series.

How You Can Apply Electrical Logic

Before you wrap your new harness in electrical tape, follow Liam’s "Signal Purity Checklist":

- 1. Gauge Selection: Never use hardware-store wire; utilize TXL or GXL cross-linked polyethylene wire which resists heat up to 125°C (257°F) to prevent harness melting in tight engine bays.

- 2. Connector Integrity: Replace legacy glass fuses with modern Sealed Power Distribution Modules (PDM) or blade-style fuse blocks to prevent oxidation-related voltage drops.

- 3. Termination Forensics: Use professional ratcheting crimp tools—never solder joints in high-vibration areas, as solder creates a "brittle point" that can fracture over time.

Verified Technical Authority

-

B.Eng. in Electrical & Electronic Engineering - University of Manchester. Specialist in Signal Processing.

-

Former Consultant for UK Motorsport Loom Manufacturers, specializing in ECU integration for classic restorations.

-

Senior Editor for C10MT's Technical Accuracy Pass (TAP), overseeing all electrical, wiring, and EFI documentation.

Electrical & EFI Guides by Liam