The Architecture of Strength

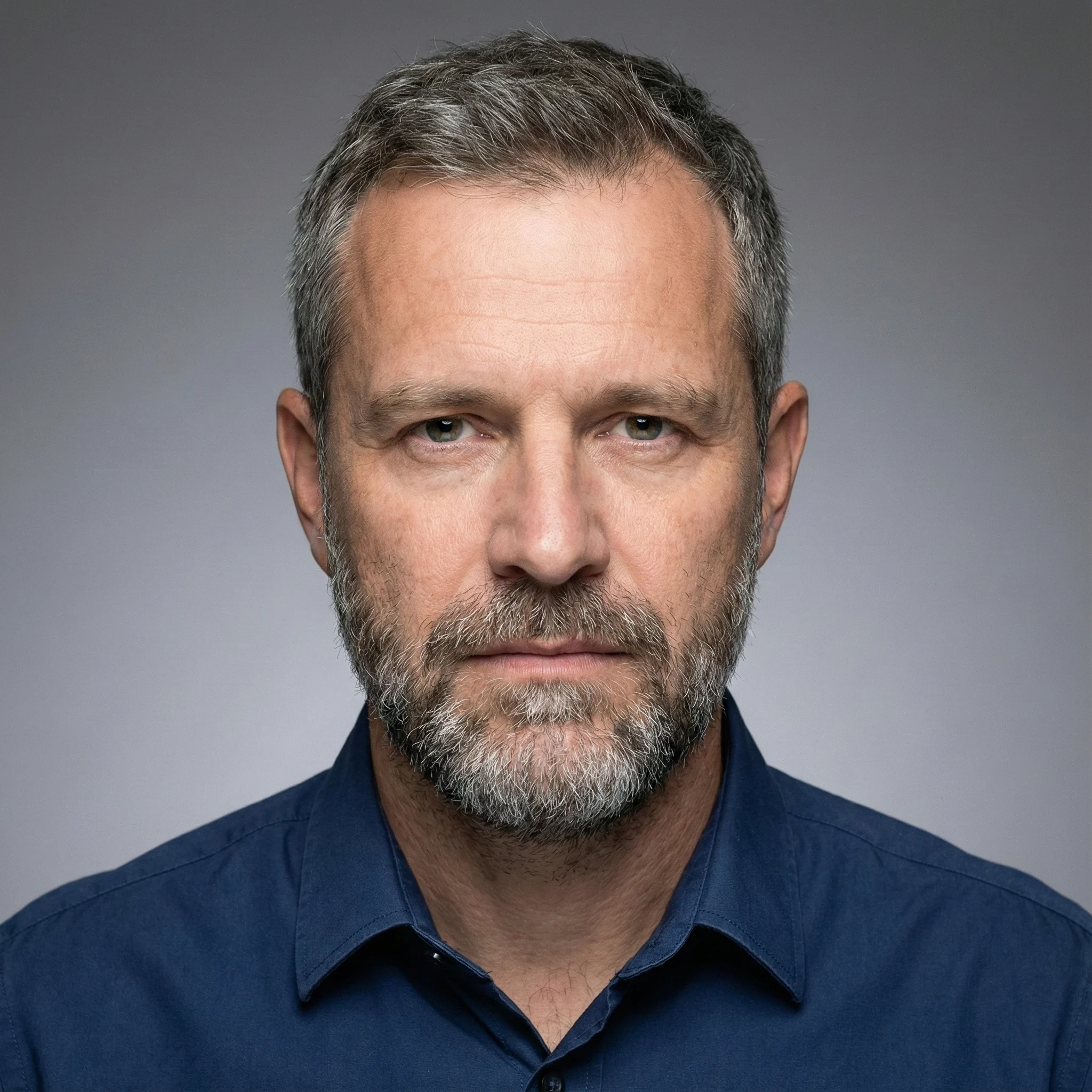

In the high-performance world of Chevrolet C10 restomods, the strength of the build is determined not by the paint, but by the integrity of the unseen steel. For Paul Koch, an Austrian-trained mechanical engineer and master fabricator, metalwork is a discipline of absolute precision. Based on the rigorous standards of European heavy industry, Paul views every custom bracket and weld bead as a critical component in Structural Safety Architecture.

Paul’s core philosophy is "Structural Longevity." He specializes in custom bracket fabrication and auditing the specialized tools required for professional-grade restorations. His work at C10MT focuses on solving the challenges of metal fatigue and rust propagation, providing enthusiasts with the technical blueprints to reinforce their classic trucks for modern high-torque powertrains. "A weld is not just a joint; it is a fusion of eras that must endure for another fifty years," Paul emphasizes.

Technical Insight: The Heat Input Ratio

When welding thin-gauge 1960s C10 body panels, many fabricators struggle with warping or "oil-canning." Paul utilizes a thermal management protocol based on ISO 2553 (Welding and allied processes) and SAE J403 (Chemical Compositions of Carbon Steels). He recommends utilizing a Stitch-Welding Sequence with a cool-down period between every 0.5-inch bead to minimize the Heat-Affected Zone (HAZ), preserving the crystalline structure of the original GM steel.

Case Study: The 1965 High-Torque Frame Reinforcement

In 2023, Paul engineered a custom "boxing" and crossmember relocation for a 1965 C10 receiving a 700+ HP supercharged engine. By utilizing ASTM A36 structural steel plates and a verified TIG welding sequence, he successfully eliminated frame twist under load. The project achieved a 40% increase in torsional rigidity while maintaining factory appearance. This technical blueprint has become the Evergreen standard for chassis reinforcement in our Structural Series.

How You Can Apply Fabrication Logic

Before you strike your first arc on a C10 restoration, follow Paul’s "Fusion Integrity" checklist:

- 1. Material Decarburization: Always strip old paint and primer 2 inches away from the weld zone; legacy lead-based primers can contaminate welds and cause catastrophic structural failure.

- 2. Tool Calibration: Ensure your welder’s gas flow rate is verified using a flowmeter—never rely on the tank regulator alone for critical TIG shielding.

- 3. Stress Relieving: For heavy-duty brackets, utilize a slow-cool process in a sand bucket to prevent brittle fractures at the weld toes, especially in load-bearing suspension points.

Verified Technical Authority

-

Dipl.-Ing. in Mechanical Engineering - TU Wien (Vienna University of Technology). Specialist in Metallic Structures.

-

Certified IWE (International Welding Engineer) with 20+ years of industrial fabrication experience.

-

Senior Editor for C10MT's Technical Accuracy Pass (TAP), overseeing all fabrication, welding, and tool auditing guides.

Fabrication & Tool Guides by Paul