Ultimate Chevrolet C10 Buyer's Guide: Sourcing the Perfect Project Truck

The Chevrolet C10 has ceased to be merely a used pickup truck; it has matured into a definitive asset class within the broader automotive collectibles market. At C10 Modern Techniques (C10MT), we see the trajectory of the market reflecting a sophisticated bifurcation between "driver-quality" enthusiasts' vehicles and "blue-chip" investment-grade restorations. The era of discovering a pristine, rust-free survivor in a rural barn for a nominal sum has largely concluded, replaced by a highly scrutinized marketplace where provenance, structural integrity, and option scarcity dictate value with ruthless precision.

Current market intelligence suggests that while the precipitous price climbs observed between 2020 and 2023 have stabilized, the floor for entry-level project trucks continues to rise. This is driven by a demographic shift: as Baby Boomers transition out of the hobby, Gen X and Millennials are entering with significant capital, specifically targeting the "Action Line" (1967–1972) and increasingly the "Squarebody" (1973–1987) generations. These buyers view the C10 not as a farm implement, but as a nostalgic touchstone of 1970s and 80s Americana, fueling demand for trucks that balance vintage aesthetics with modern drivability.

However, the restoration landscape is complicated by macroeconomic factors. The potential for aggressive trade tariffs on imported automotive components—specifically stamped sheet metal from Taiwan and Mexico, which constitute the bulk of the restoration aftermarket—threatens to increase the cost of a "frame-off" restoration by an estimated 25-30%. Consequently, the financial viability of a project truck is no longer solely a function of its purchase price but is heavily weighted by its completeness and the condition of its non-reproducible components. A truck requiring a full catalog of replacement panels may now be a financial liability regardless of a low entry price, whereas a solid, complete survivor commands a premium that reflects the avoided cost of parts procurement.

The C10 remains the darling of the aftermarket, boasting support that rivals the Ford Mustang and Chevrolet Camaro. Virtually every component, from cab floors to trim clips, is available. Yet, this abundance creates a trap for the unwary: the "Catalog Build." Trucks assembled entirely from reproduction parts often lack the fit, finish, and "soul" of those retaining original sheet metal.

Therefore, the discerning buyer must become a forensic investigator, capable of distinguishing between factory steel and reproduction tin, between original patina and artfully concealed neglect. This report serves as a comprehensive technical manual for that investigation. For a broader historical perspective, you can explore our database of Chevrolet C10 motor vehicles, dissecting the structural, mechanical, and identification nuances of the three primary generations.

Chapter 1: The First Generation (1960–1966) – The Independent Revolution

The 1960 model year was not merely a stylistic update; it was a fundamental engineering pivot that decoupled the American pickup from its "tractor-with-a-cab" heritage. According to the GM Heritage Center technical archives, 1960 introduced the "drop-center" ladder frame, lowering the center of gravity and enabling the Independent Front Suspension (IFS).

Expert Insight: For the investor, the 1960–1966 era represents the highest entry barrier in terms of metalwork. Unlike later generations, these trucks lack the modularity of 1973+ models, making "completeness" your primary metric for valuation.

1.1. The Torsion Bar Anomaly (1960–1962): An Engineering Dead-End

The inception of the C10 series was defined by a departure from traditional truck engineering: the torsion bar front suspension. Chevrolet aimed to provide a "pillowy" ride quality comparable to luxury sedans of the era. However, while innovative at the time of release, this specific three-year design represents a significant logistical and financial liability for long-term restoration projects.

- The Logic of Scarcity: Torsion bars function by twisting high-tensile steel to absorb kinetic energy. Over decades of service, metal fatigue becomes a primary structural concern. Because this specific geometry was utilized for only a 36-month production window, major restoration suppliers such as LMC Truck and Classic Industries historically omit these components from their reproduction catalogs. Procurement typically requires navigating the secondary market for New Old Stock (NOS) or salvaged donor chassis.Verification Note: It is critical to verify real-time component availability via supplier inventory and specialized NOS listings before committing to a torsion-bar chassis restoration.

- Case Study (The "Leaning" Truck): A common red flag during field inspections is a vehicle with a noticeable list toward the driver's side. On 1963–1966 models, this is typically a routine coil spring replacement. On 1960–1962 models, it often signifies a stripped torsion "key" or a hairline fracture in the bar—specialized components that are notoriously difficult to source through standard retail channels.

- Action Guideline (The Crossmember Audit): Inspection must extend beyond the bars to the center crossmember anchor points. Owners should degrease the frame rails to check for structural compromise. Decision Threshold: If longitudinal stress cracks exceeding 2 inches are detected, or if there is significant deformation in the crossmember mounting flange, the frame is structurally compromised. Such repairs require a certified structural welder to restore the suspension geometry to factory specifications.

- Technical Risks of the "Crossmember Swap": To bypass parts scarcity, many builders opt to swap the front clip with 1973–1987 components. However, improper welding techniques pose a high risk of frame warping due to excessive heat soak, which can permanently alter the truck's track. Post-modification, a professional laser alignment check is mandatory to ensure the wheels are square to the frame; failure to do so often results in "crab-walking" and accelerated tire wear. While this improves drivability, it generally removes the vehicle from "Investment Grade" categories among purist collectors.

The "Nostril" Hood: Body Panel Sourcing (1960–1961)

Distinct from chassis mechanics, the 1960 and 1961 models possess a unique body-panel requirement: the "nostril" hood, characterized by dual oval air intakes at the leading edge. This is a separate cost-center for restorers because these hoods were complex to stamp and are not widely reproduced to factory-gauge thickness. A damaged or missing "nostril" hood represents a high-cost procurement hurdle, as they are non-interchangeable with the refined 1962–1966 hood profiles.

Ultimately, while the 1960–1962 models offer the most unique aesthetic of the generation, they require a restorer who is either a master fabricator or possesses the financial flexibility necessary to navigate a depleted parts market.

1.2. The Transition to Coils (1963–1966): The Restorer's "Sweet Spot"

The year 1963 marked a fundamental engineering shift for the C10 with the standardization of the coil-spring Independent Front Suspension (IFS). This architecture proved so robust that it remained the blueprint for the Chevrolet pickup chassis for over two decades. For many restorers, this era represents a "sweet spot" where the iconic mid-century aesthetic meets a platform that significantly reduces the technical and financial barriers to modernization.

- Standardized Interchangeability: The move to coil springs in 1963 revolutionized long-term maintenance. Because the core suspension geometry remained consistent through subsequent generations (up to 1987), restorers can access a vast secondary market of drop spindles, power steering conversions, and modern braking systems. This cross-generational compatibility makes the 1963–1966 chassis the most "restomod-friendly" platform of the era.

- The "Dogleg" A-Pillar (1960–1963) Technical Vulnerability: Cabs produced prior to 1964 utilized a wraparound windshield with a distinct "dogleg" bend in the A-pillar. This geometry is prone to high-pressure stress points; excessive frame flex or worn body mounts can transmit enough torque to the glass to cause spontaneous cracking. Furthermore, the complex curvature makes weatherstripping replacement more labor-intensive and prone to failure.

- The "Flat-Glass" Logic (1964–1966): The transition to a flatter windshield in 1964 significantly improved cabin integrity. This design change can materially reduce the cost and complexity of weatherstripping repairs while providing a superior seal against water intrusion. For the buyer, a 1964–1966 cab often represents a lower risk of "floorboard rot" and water-damaged electrical components behind the dashboard.

- The 1966 Performance Milestone: The 1966 model year is a highly valued "Evergreen" asset because it introduced the 327 cubic inch V8 and the Turbo-Hydramatic transmission. This powertrain often eliminates the immediate need for an engine swap for highway use, as it provides sufficient torque for modern traffic speeds. Verification Instruction: Always confirm engine provenance via VIN decoding and engine pad stamping photos (located behind the alternator) to ensure the vehicle is an authentic factory V8 model before finalizing an investment-grade valuation.

- Action Guideline (The Drip Rail Audit): Inspect the underside of the exterior roof drip rails for "cauliflower" bubbling. Because these joints were historically finished with lead-based sealants, they are primary sites for hidden oxidation. Safety Note: If repairs are necessary, avoid dry grinding or sanding these areas without professional-grade respiratory protection to mitigate exposure to legacy lead particulates. Compromised drip rails often indicate deep-seated rust within the internal A-pillar structure.

Ultimately, while 1963 provided the chassis foundation, the 1964–1966 models offer the most refined ownership experience. They provide a predictable path for the builder—balancing historical charm with the logistical ease of readily available components and simplified body maintenance.

1.3. Rust Pathology: The Double-Wall Dilemma

First-generation C10s were engineered during an era before the widespread adoption of electro-galvanized steel. To improve Noise, Vibration, and Harshness (NVH) levels, Chevrolet utilized a "double-wall" construction for the cab roof and cowl. While this provided superior insulation, it created a conducive environment for inter-skin oxidation—a structural failure that typically originates from the inside out.

- The Sun Visor Forensic Test & Thresholds: This is a definitive test for upper cab health. Remove a mounting screw from the sun visor. Decision Threshold: If the screw threads exhibit >50% surface oxidation or deep pitting, the internal roof bracing is likely compromised. This level of decay often suggests that the roof’s structural integrity is insufficient for safe operation without a full outer-skin replacement.

- The Auditory "Crunch" Check: Apply firm pressure to the roof skin just above the windshield weatherstripping. Decision Threshold: If you detect a "crunching" sound or if rust penetration exceeds 1 inch (25mm) at any single point, the header is functionally gone. Note: Windshield header rot is a primary safety risk, as it serves as a critical load-bearing component in the event of a rollover.

- Financial Risk Assessment: Identifying roof rot early is essential for budgeting. A localized patch repair by a professional may range from $300 to $1,000, but a complete roof-skin replacement can exceed $2,500–$4,500 depending on labor rates and the condition of the inner bracing. Always verify the availability of "patch panels" versus "full skins" in supplier catalogs to gauge the feasibility of the project.

- Verifying Previous Repairs: To detect hidden "Band-Aid" fixes, use a high-strength magnet along the lower cab corners and windshield pillars. Red Flags: A failure of the magnet to stick, uneven paint textures (orange peel inconsistency), or visible weld beads under the seam sealer indicate previous non-factory repairs. Inspect for fiberglass patches, which are common in low-cost restorations but lack the structural bond of steel-to-steel welding.

- Action Guideline & Safety (Lead Warning): When cleaning or repairing drip rails or roof seams, exercise extreme caution. These joints were historically finished with lead-based sealants. Safety Protocol: Never dry sand or grind these areas. Always wear a P100-rated respirator and consider professional lead abatement if extensive metalwork is required.

Cognitive Milestone: By completing this section, you have successfully determined if your target C10 is a "Survivor" or a "Liability." If the torsion mounts (for 60-62) and the double-wall roof structure are verified as solid, you are looking at a viable investment-grade platform. In the next chapter, we will shift our focus to the "Action Line" (1967–1972) to understand why it remains the most profitable—yet most competitive—sector of the vintage truck market.

Chapter 2: The Action Line (1967–1972) – The Zenith of Design

The "Action Line" is widely considered the "blue-chip" generation of the Chevrolet C10. Its sloped hood and clean, architectural profile defined the modern pickup aesthetic. However, for the strategic investor, this era represents a technical paradox: the very design choices that contributed to its iconic beauty created severe, hidden structural vulnerabilities—specifically within the air-management systems—that require a forensic level of scrutiny during any pre-purchase inspection.

2.1. The Cowl Vent Catastrophe: A Design-Induced Failure

The cowl assembly—the structural plenum located between the hood and the windshield—is the most critical inspection point on a 1967–1972 chassis. This is not merely a cosmetic exterior panel; it is a complex junction where the firewall, A-pillars, and upper dashboard meet. Its failure is typically internal, making it a primary "hidden liability" that can undermine the financial viability of an entire project.

- The Anatomy of Decay: Chevrolet utilized a fresh-air intake system where water and debris pass through the top vent, travel down the internal "shoulders" of the cowl fenders, and exit through small drain slots at the base. Over decades, organic debris (leaves, pine needles) accumulates within this non-galvanized cavity. Because the area is nearly inaccessible without removing factory panels, this debris creates a permanent moisture trap against the raw steel.

- Actionable Audit (The 2-Gallon Water Test): To verify plenum integrity, request the seller’s permission to perform a water-shed test. Gently pour approximately two gallons of water into the top cowl vent.

Safety & Procedure: Perform this test only if the vehicle's interior is dry and sensitive electronics (such as aftermarket audio or exposed fuse blocks) are protected. Ensure the seller is present to witness the results. Water should exit immediately and cleanly from the drain ports behind the front tires. - Forensic Decision Thresholds:

- The Leak Test: If water manifests on the interior floorboards or drips from behind the dashboard, the internal plenum is perforated. This indicates a "major repair" status.

- Borescope Inspection: Use a borescope camera to inspect the internal cowl shoulders. Walk-Away Threshold: If the borescope reveals that >50% of the internal shoulder area is punctured or exhibits heavy scale, the truck should be valued as a parts donor or require a deep discount to offset structural fabrication.

- Financial Risk Assessment: Cowl repairs represent a significant range in project budgeting. Minor external patches or drain cleaning may range between $300 and $1,200. However, a full "top-hat" cowl replacement is "major surgery", requiring the removal of the windshield, hood, and doors, plus drilling out 150+ factory spot welds. Market Estimate: Typical professional quotes for a complete cowl reconstruction can range from $5,000 to $8,000 in labor alone, depending on regional rates and the extent of internal A-pillar damage.

- Verification of Previous Repairs: When inspecting a truck with a pristine exterior, look for "tell-tale" signs of cowl cover-ups. Inspect the seam sealer at the base of the windshield; if it appears excessively thick or uneven, it may be masking a "caulk-and-paint" fix rather than a steel replacement. Check for mismatched paint layers or modern rivets where factory spot welds should be.

Ultimately, a 1967–1972 C10 with a compromised cowl is a technical paradox. While the exterior may exude "Zenith of Design" aesthetics, the underlying structural decay can turn a profitable investment into a financial liability. Unless the vehicle's price is adjusted to account for the specialized metalwork required, a rotted plenum should serve as a definitive signal to proceed with extreme caution.

2.2. The 1967 "One-Year-Only" Sourcing Trap

The 1967 model year occupies a prestigious yet treacherous position in the C10 hierarchy. It is the only year of the Action Line to offer the "Small Rear Window" and side-marker-less fenders, making it a "Holy Grail" for purists. However, the 1967 is a transitional hybrid; while the body is new, much of the chassis—including the brake master cylinder mounting and the rear suspension geometry—retains 1960–1966 characteristics. This "year-one" status creates a high-risk environment where parts interchangeability is significantly restricted.

- The Interior Hardware Logjam: The 1967 cabin is a repository of unique components, including dash pads, radio knobs, and window cranks. Forensic Identifier: 1967 interior door handles are unique "squeeze" types; the 1968–1972 models transitioned to "pull" designs. Market Estimate: Due to collector demand and lack of high-quality reproductions for certain trim pieces, these items can command premiums 3x to 4x higher than their 1968 equivalents.

- The Parking Brake "Firewall" Complexity: In 1967, Chevrolet utilized an under-dash pull-handle for the parking brake, which shifted to a floor-mounted pedal in 1968. Because the firewall stampings are fundamentally different, correcting a "parts-bin" truck back to factory specifications requires extensive metal fabrication. Verify that the parking brake mechanism is present, as year-correct pull-handle assemblies are increasingly scarce on the secondary market.

- Investment Threshold (The 30% Rule): If a 1967 project is more than 30% "gutted" (missing major interior trim and hardware) and lacks a verifiable parts record, the cost of sourcing year-correct components may exceed the truck's projected value increase. In such cases, a more modular 1968–1972 model often provides a superior return on investment.

- Actionable Investigation (The Frame Stamping): To detect "Frankenstein" builds, cross-reference the VIN plate on the driver's door pillar with the frame stamping (located on the driver's side rail near the steering box). A mismatch indicates a cab swap, which effectively voids the truck’s "Investment Grade" status due to the loss of provenance and matching-numbers originality.

- Professional Sourcing Tactics: If committed to a 1967 build, standard catalogs will often fail to provide specialized trim. Strategic builders should pivot to:

- Specialized Swap Meets: Focus on vendors specializing in "New Old Stock" (NOS) or "take-off" original parts.

- Provenance Verification: Request invoices or inventory photos from the seller to prove that claimed "original" parts are actually year-correct for 1967.

Ultimately, while 1967 offers the cleanest aesthetic of the generation, it requires a buyer who prioritizes "completeness" over a low entry price. Without a near-complete interior and a verified chassis-to-body match, a 1967 project risks becoming a financial sinkhole where the cost of rare trim outweighs the vehicle's market appreciation.

2.3. 1971–1972: The "Golden Standard" for ROI

The final two years of the Action Line generation are widely regarded as the "Golden Standard" for return on investment (ROI). This period marked a definitive mechanical pivot: the introduction of standard front disc brakes and a transition from the traditional 6-lug pattern to a 5-lug "5 on 5" bolt pattern. These upgrades transitioned the C10 from a vintage utility vehicle into a platform capable of modern traffic conditions with minimal modification.

60-Second Mobile Audit: Check all four wheels. If the bolt patterns don't match (5-lug front/6-lug rear), or if you see "bolt-on" spacers/adapters, you are looking at a budget conversion rather than a factory-standard or professional-grade build.

- Market Intelligence & Valuation: Standardized disc brakes and 5-lug axles typically command an approx. 15–20% market premium over 1967–1970 models, according to recent collector market estimates. This "investment-grade" status is driven by avoided costs; a 1972 model is highway-ready in its factory configuration, whereas earlier models require significant capital to achieve the same level of safety and wheel availability.

- The "Lazy Conversion" Forensic Audit: Many earlier trucks have undergone partial conversions using salvaged 1971–1987 components.

Identifying Signs: Look for non-OEM weld marks on the spindles, mismatched paint colors between the hub and control arms, or the presence of bolt-pattern adapters.

Decision Threshold: If the rear axle does not match the front 5-lug pattern, request a full conversion quote from a local specialist or demand a price reduction to cover the cost of a matching rear differential swap. - The Brake Booster "Dead Zone": Inspect the master cylinder. Factory 1971–1972 models utilize a specific dual-reservoir master cylinder with a dedicated proportioning valve to manage disc/drum pressure bias.

Technical Warning: If an earlier truck was converted to disc brakes but still uses a drum-only master cylinder, the braking performance will be uneven and potentially hazardous. Signs of a non-conforming system include bubbling fluid at the seals or a "spongy" pedal feel that persists after bleeding. Approximate market quotes to rectify this with a correct valve and master cylinder setup range from $400 to $800. - Chassis & Aesthetics: While 1971–1972 parts are generally more accessible, certain trim pieces command steep premiums. The original "egg-crate" grille is highly sought after; typical market quotes for a pristine, original-stamped 1972 grille can approach $1,000. Expert Decision: If a borescope inspection of the suspension mounts shows incorrect fitting or compromised welds from a prior conversion, walk away—improper geometry at these points is often unfixable without a frame-off intervention.

Pre-Purchase Checklist: 1971–1972 Action Line

- Count the Lugs: Verify a matching "5 on 5" pattern on all four corners.

- Master Cylinder Check: Confirm the presence of a disc-specific dual-reservoir cylinder and proportioning valve.

- Spin the Hubs: Listen for bearing noise and check for excessive "play" in the 5-lug conversion.

- Grille Integrity: Inspect the egg-crate grille for metal fatigue or pitting (high-cost replacement item).

Cognitive Milestone:You have now completed the forensic audit for the "Action Line" era. You possess the criteria to distinguish between a high-value survivor and a compromised "parts-bin" build. In the final chapter, we will analyze the "Squarebody" generation (1973–1987), where rust pathology remains a threat, but mechanical modularity becomes your greatest asset.

2.4. Trailing Arm Suspension: Performance vs. Structural Risk

The defining mechanical feature of the Chevrolet C10 is its coil-spring trailing arm rear suspension—a design famously utilized in NASCAR for its superior articulation and ride quality. However, from a restoration perspective, this architecture possesses specific metallurgical and geometric "blind spots" that present significant safety risks if not subjected to a forensic audit during inspection.

- The "Double-Wall" Oxidation Hazard: C10 trailing arms are constructed from two C-channel steel stampings welded together to form a box. This hollow design acts as a natural trap for road salt and moisture.

Field Investigation (The Acoustic Tap Test): Use a small hammer to tap along the length of the arms. A clear, metallic ring indicates healthy steel; a dull, heavy "thud" indicates internal mud accumulation or advanced scaling.

Decision Threshold: If any perforated rust (holes) is detected or if the hammer creates a dent, the arm is structurally compromised. Replacement trailing arms typically cost between $400 and $700 per set, excluding labor. - The "Tail Wag" Safety Risk: The front pivot point of each trailing arm is secured by a large rubber isolator bushing.

Forensic Bushing Test: Use a pry bar to apply pressure between the arm and the mounting bracket.

Decision Threshold: If there is >1/4 inch of lateral movement or visible cracking in the rubber, the bushings have collapsed. This allows the rear axle to steer independently of the chassis, causing dangerous "wandering" during lane changes. Professional shop labor to remove seized bolts and press in new bushings often ranges from $400 to $900. - Crossmember Fatigue & "Lazy Repairs": The high torque loads from V8 engines are transmitted directly to the center crossmember. Over decades, this results in stress cracks radiating from the mounting rivets.

Identifying Signs of Substandard Repair: Inspect for "bird-poop" welds (lacking penetration), non-grade-8 hardware replacing factory rivets, or mismatched paint colors around the pivot that may mask cracks.

Decision Threshold: If any hairline crack exceeds 1 inch in length, or if reinforcement plates show signs of edge-lifting, the repair is a safety liability. Safety Note: Always use jack stands and wear eye protection when inspecting these under-chassis components. - Trailing Arm vs. Leaf Spring Valuation: While most C10s featured trailing arms, some heavy-duty or special-order models utilized leaf springs.

Market Intelligence: Original trailing arm trucks typically command an approx. 10–15% premium in the Restomod market (based on collector market estimates), as the design allows for significantly lower ride heights while maintaining superior ride quality.

Quick Forensic Check: Rear Suspension

- The Tap Test: Verify the internal density of both trailing arms.

- Pry-Bar Audit: Check for excessive "play" at the front pivot mounts (>1/4 inch is a fail).

- Rivet-Spider Scan: Search for hairline cracks or loose rivets on the center crossmember.

- Weld Integrity: Ensure any previous reinforcement is professional-grade (smooth, deep penetration beads).

Cognitive Milestone:By documenting the cowl integrity, the 1967-specific nuances, braking standards, and trailing arm health, you have completed the forensic audit for the "Action Line" era. You now possess the data required to distinguish between an expensive liability and an investment-grade survivor. In the final chapter, we will analyze the "Squarebody" generation (1973–1987), where mechanical modularity becomes your greatest asset, but rust remains the primary adversary.

Chapter 3: The Squarebody Era (1973–1987) – The Rising Giant

Running for 14 production years, the "Rounded Line"—commonly known as the Squarebody—is the most prolific and culturally dominant generation in Chevrolet's history. While its abundance once made it a budget-friendly entry point, the Squarebody has transitioned into a primary investment target. However, its long production run is a double-edged sword: the vast technical differences between an early 1973 and a final-year 1987 mean that "year-correctness" is now the primary driver of value. To invest wisely, one must look past the iconic silhouette and audit the structural integrity hidden beneath the sheet metal.

3.1. The Hood Kink and Firewall Fatigue: A Leverage Failure

The 1973–1980 models suffer from a notorious structural failure known as the "Hood Kink." This is not merely a cosmetic blemish; in the world of forensic auditing, it is a loud signal of neglected maintenance and metallurgical stress. Understanding this failure is key to evaluating how well a truck was cared for over the decades.

- The Physics of Failure: The massive, flat hood acts as a high-leverage arm. When factory hinges seize due to age, the force required to close the hood is transferred into the center of the sheet metal, causing it to buckle forward of the mounting point.

- Secondary Pathology (Firewall Stress): Repeatedly forcing seized hinges flexes the firewall mounting pockets. Inspect these areas for vertical hairline cracks.

- Expert Remedy: If cracks are present, they must be "stop-drilled" and TIG-welded. A simple reinforcement plate without a proper weld is a "lipstick fix" that leads to eventual cowl failure and cabin noise.

3.2. Steering Box Frame Cracks: The "Death Wobble" Source

Perhaps the most critical safety audit for any 1973–1987 chassis is the inspection of the driver-side frame rail. Because the Squarebody was often used as a heavy-duty workhorse or modified with oversized tires, the frame section where the steering box mounts is a high-fatigue zone that demands a forensic "Buddy Test."

| Symptom | Root Cause | Investment Risk |

|---|---|---|

| Frame "Breathing" | Metal fatigue near bolts | High:Safety failure imminent. |

| Vertical Cracks | Torsional stress | Critical:Requires frame repair. |

| Steering Wander | Loose box mounting | Moderate:May require bracing. |

- The "Buddy Test" Protocol: With the engine running, have an assistant cycle the steering wheel rapidly between 10 and 2 o’clock. Watch the steering box from the wheel well; if it moves independently of the frame, the metal is fatigued.

- Action Plan: If cracks are detected, weld-in "fish-plate" kits and bolt-in braces (such as those from Offroad Design) are mandatory. For an investor, finding these upgrades already installed is a sign of a "maintenance-forward" owner.

3.3. 1981 Facelift and the Aerodynamic "Bifurcation"

In response to the early 80s fuel crises, GM performed a major aerodynamic overhaul in 1981. This created a "parts-matching trap" for the unwary collector. While a 1979 and an 1982 look similar at a distance, they share surprisingly few front-end components, making "Frankenstein" builds easy to spot for the trained eye.

The Interchangeability Myth: You cannot mix front-end clips (hood, fenders, cowl) between the 1973–1980 and 1981–1987 eras without significant modifications to the wiper transmission and cowl panel. If you encounter an '85 model with a '74 "round-eye" nose, be wary. These swaps often involve cobbled wiring and poor weather sealing. In the collectibles market, a mismatched front clip suggests a major collision history where the owner used whatever parts were cheapest at a junkyard.

3.4. The Saddle Tank Safety Evolution

The Squarebody is famous for mounting fuel tanks outside the frame rails ("Saddle Tanks"). While technically legal in their era, modern safety standards and restoration trends have moved toward relocation. As an auditor, you must judge the quality of these modifications, as a poorly executed tank swap is more dangerous than the original factory setup.

- The Restoration Standard: The "Evergreen" trend is relocating the tank to the rear of the frame (between the rails), typically utilizing a 1987–1991 Blazer tank.

- Audit Checklist: Inspect the rear crossmember. Crude torch cuts or thin-gauge metal straps indicate a DIY job. A professional conversion uses a dedicated crossmember kit and properly routed, shielded fuel lines.

3.5. The 1987 "Holy Grail" (The R/V Series)

In 1987, GM changed the designation from C/K to R/V for the final year of this body style. This single year represents the pinnacle of Squarebody technology and is the "Holy Grail" for those seeking a vintage aesthetic with modern drivability.

The TBI Advantage: 1987 was the first year for factory Throttle Body Injection (TBI) on the V8 engines. This system replaced the notoriously finicky carburetors, offering modern reliability, easy cold starts, and consistent fuel delivery. Because of this, an original 1987 R10 (2WD) or V10 (4WD) commands a 25–30% market premium. It is the logical choice for an investor who wants a truck that will hold value while requiring the least amount of mechanical intervention.

Cognitive Milestone: You have now progressed from the "Independent Revolution" of the 60s to the "Structural Safety" challenges of the Squarebody. You know that a "Death Wobble" is often a frame issue, not just a steering issue, and that 1987 represents the ultimate mechanical benchmark. In the next section, we move into the Forensic Triple-Match Audit to ensure your target truck is a genuine original and not a high-priced clone.

Chapter 4: Forensic Identification – VINs, SPIDs, and Provenance

Provenance is evidence. Treat VINs, SPIDs, and service records as forensic data: corroborate them, expose inconsistencies, and let documented facts decide whether the truck is an authentic survivor or a cosmetically altered impostor.

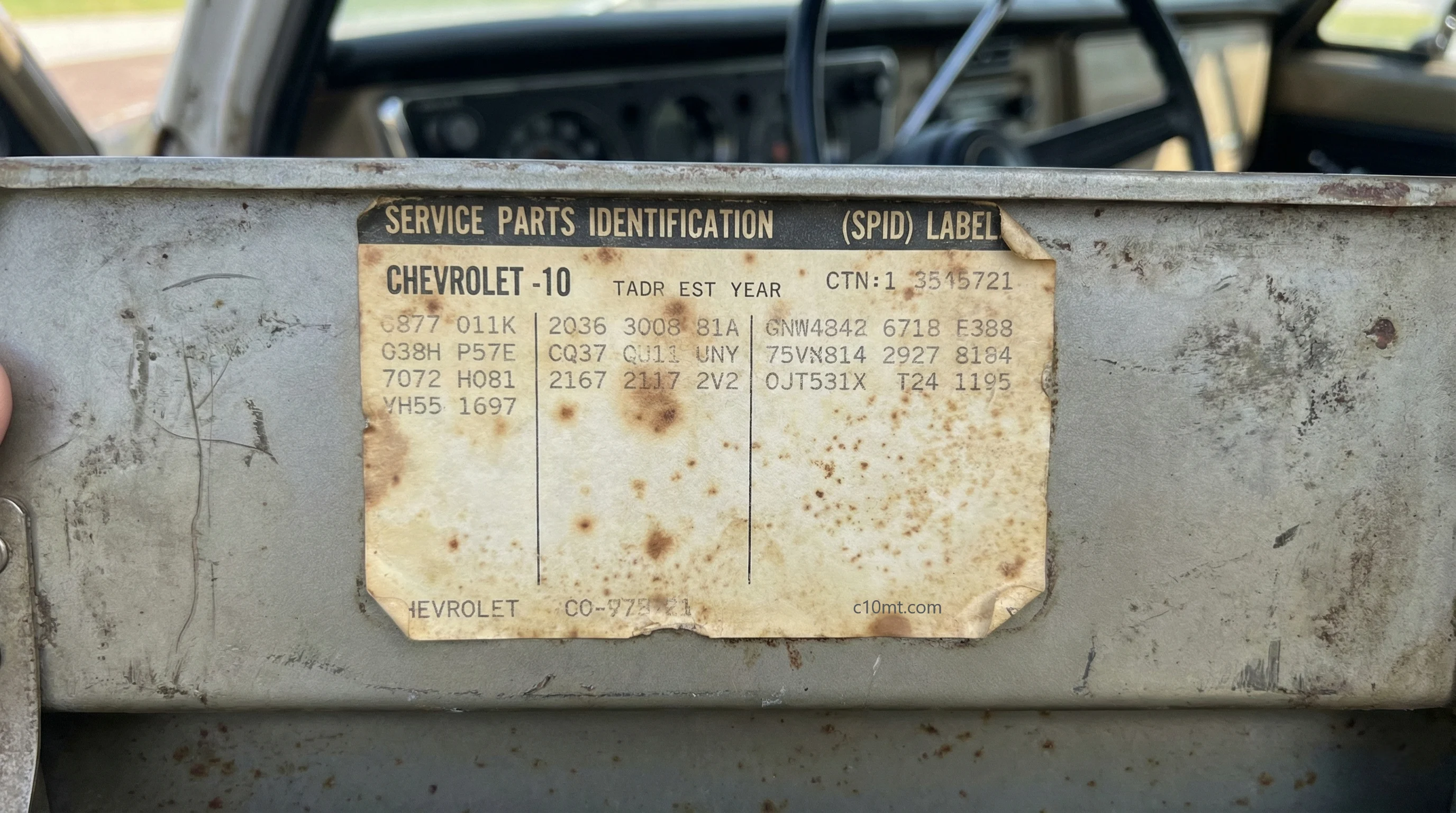

4.1. The Service Parts Identification (SPID) Label: The DNA Record

The Service Parts Identification (SPID) label is a factory-affixed document that serves as the "DNA record" of a Chevrolet C10. It lists every Regular Production Option (RPO) code—from engine displacement and rear-axle ratios to specific trim levels—assigned to that specific chassis. In a market where a factory-documented "Big Block" can command a significant premium over a standard V8, the ability to verify the SPID's authenticity is a critical forensic skill.

- Audit Locations:

1967–1972: Located exclusively on the inner face of the glovebox door.

1973–1987: Most commonly found on the inner glovebox door, though some models feature a secondary label on the driver’s side inner fender well (under-hood). - The "Repro" Detection Protocol: High-quality digital reproduction labels are common. To detect a fake, look for ink-bleed patterns: Original factory labels often used impact or dot-matrix printers where the ink bleeds slightly into the paper fibers. Modern laser-printed fakes produce "pixels" that sit on top of the paper.

- Decision Threshold: If the label appears bright white while the surrounding glovebox paint shows age and patina, consider the label a reproduction.

- Rule of Thumb: Aging consistency is non-negotiable; the paper oxidation (foxing) must match the vehicle's environmental history. - The Swapped Door Discrepancy: A common form of SPID fraud is a swapped glovebox door.

- Decision Threshold: The VIN on the SPID must match the Frame VIN and the Dash VIN. If any of these three do not match, the options list is legally irrelevant to the chassis.

- Walk-Away Point: A mismatched VIN on the SPID is an immediate signal to halt the investment-grade valuation process. - Financial Risk & Case Study: Market estimates suggest that a factory-documented "Super Cheyenne" with an LS3 (402ci Big Block) can lose approx. 30–40% of its collector value if the SPID is missing or proven to be a fake. To corroborate a suspicious SPID, cross-verify the engine block casting numbers and the "Protect-O-Plate" (if available). A "High-Option" paper trail without matching physical heavy-duty components is a sign of a "cosmetically altered impostor."

- Doubt Handling Procedure: If you suspect the SPID is not original:

- Documentation Request: Require the seller to provide historical invoices, build sheets, or restoration photos.

- Physical Audit: Compare 3–5 key RPOs (e.g., G80 Positraction, J50 Power Brakes) with the actual parts on the truck. If more than one does not match, treat the truck as a base-model build.

- Expert Consultation: For high-value transactions, consult an independent marque specialist or reference an RPO database to verify that the listed codes were actually available for that production month.

- Preservation Note: If an authentic label is present, avoid cleaning it with liquids. Protect it from direct sunlight and high humidity. For highly valuable survivor trucks, consider an archival-grade clear laminate shield to prevent further degradation of the vintage ink.

The Forensic SPID Checklist

- Triple VIN Match: SPID VIN = Frame VIN = Dash VIN. (Mismatch = STOP).

- The Tactile Test: Impact-printed ink vs. smooth laser-printed pixels.

- Environmental Matching: Does the label's "foxing" match the cab’s patina?

- RPO Physical Audit: Do the physical axle, brakes, and trim match the paper?

Cognitive Milestone: By validating the SPID label and cross-referencing it with the physical build, you have moved beyond the "buyer" phase into "forensic auditor." You are now letting documented facts—not the seller's narrative—determine the truck's value. Next, we will analyze the ultimate piece of physical evidence: the Frame Rail Stamping.

4.2. Decoding the VIN: The Triple-Match Audit

Core objective: The Triple‑Match Audit is the definitive safeguard for a C10 investor’s capital. In the collector truck market, a VIN is far more than a simple identification number; it is a legal and financial contract. Treating the VIN as a three-part verification process allows you to either confirm a vehicle's historical provenance or expose hidden liabilities that could slash tens of thousands of dollars from the truck's resale value if discovered too late.

How to use it (in plain terms): Begin with the legal documentation: verify the Title for clarity and ensure no suspicious corrections are present. Next, physically inspect the VIN plate (located on the driver’s door pillar for early models or the dashboard for later ones) and cross-reference it with the Title. Finally, you must locate the frame stamping—the ultimate "source of truth"—typically found on the top of the driver-side frame rail. If all three numbers align perfectly, you have a verified chain of identity. If even a single digit is mismatched, you must pause the transaction immediately.

Why this matters: Even a minor mismatch is often the primary indicator of a "cab swap", a cloned title, or a truck reassembled from undocumented donor parts. For a serious collector, the Triple-Match Audit provides the necessary data to either negotiate a steep discount or walk away from a potential legal and financial nightmare.

4.2.1. Phased VIN Decoding Tables

Mastering the audit requires understanding that GM’s coding logic evolved significantly as the C10 transitioned from a basic work tool to a lifestyle icon. Decoding is not merely about reading digits; it is about spotting historical anachronisms. For instance, the 1964 transition changed the chassis identification logic, often confusing buyers who assume all early-60s trucks follow the same pattern. The tables below allow you to verify if the truck’s current mechanical setup matches its factory "birth certificate."

| Position | Meaning | Code Analysis & Examples |

|---|---|---|

| 1st | Chassis Type | C(2WD),K(4WD).Note: 1964+ move. |

| 2nd | Engine Type | 1(Inline-6),3(V8). |

| 3rd-4th | GVW/Class | 14(1/2 Ton),15(Long Bed 1/2 Ton). |

| 5th | Model Year | 4(1964),5(1965),6(1966). |

As the C10 entered the "Action Line" era in 1967, the VIN architecture became more descriptive to reflect the surge in available options. This era (1967–1972) currently sees the highest market volatility, making accurate decoding a critical skill. If a VIN indicates an Inline-6 ("S") but the truck is sold as a Big Block V8, you have identified a non-original swap that must be factored into the valuation. The following table highlights the critical markers for this high-value generation.

| Position | Meaning | Code Analysis & Examples |

|---|---|---|

| 1st | Chassis Type | C(2WD),K(4WD). |

| 2nd | Engine Type | E(V8),S(Inline-6). Note: "S" is often V8-swapped. |

| 3rd | Tonnage | 1(10 / Half-Ton),2(20 / Three-Quarter Ton). |

| 4th | Body Style | 4(Pickup),6(Suburban). |

In 1973, with the launch of the "Square Body" generation, Chevrolet introduced a more complex 13-digit VIN system. This era requires even closer scrutiny, as the coding logic for engines and manufacturing plants became more granular to accommodate higher production volumes and stricter emissions standards. Use the following table to verify the authenticity of mid-to-late 70s models.

| Position | Meaning | Code Analysis & Examples |

|---|---|---|

| 1st | Division | C(Chevrolet),T(GMC). |

| 2nd | Chassis Type | C(2WD),K(4WD). |

| 3rd | Engine Code | V(292 I6),D(250 I6),U(305 V8),L(350 V8). |

| 4th | Series/Tonnage | 1(10 Series / Half-ton),2(20 Series / 3/4 ton). |

| 5th | Body Style | 4(Fleetside/Stepside Pickup). |

| 6th | Model Year | 3(1973) throughA(1980). |

A critical detail for this era is the Engine Code (3rd Position). During the oil crisis of the 70s, many trucks were swapped with smaller or larger engines. If your VIN displays an "L" (high-value 350 V8) but the engine block reflects a 305 or an Inline-6, you have clear evidence of a non-original replacement, which should be leveraged during price negotiations.

4.2.2. Forensic Decision Matrix

Identifying a discrepancy is only the first step; the true value of an expert auditor lies in the commercial interpretation of that data. A mismatch does not always necessitate walking away, but it always demands a price adjustment or a demand for further documentation. This Decision Matrix serves as your commercial shield, offering objective action steps based on the severity of the inconsistencies uncovered during your Triple-Match Audit.

| Scenario | Risk Level | Action Step |

|---|---|---|

| All Three Codes Match | Verified | Proceed with detailed mechanical and body inspection. |

| Title ≠ Frame | Legal Red Flag | STOP.Request a title correction or terminate the deal immediately. |

| Dash Plate ≠ Frame | Cab Swap | Likely a "Frankenstein" truck. Use a borescope to search for hidden VINs. |

| VIN = I6 / Truck = V8 | Engine Swap | Identify as non-original engine. Reduce valuation by 15–25% based on market data. |

4.2.3. On-Site Forensic Checklist

In the high-pressure environment of a negotiation, it is easy to overlook a single digit or forget a critical stamping location. Adopting a clinical "Standard Operating Procedure" (SOP) ensures your inspection remains objective. This 5-step checklist moves you from a casual observer to a forensic auditor, ensuring no hidden detail is missed.

Field Forensic SOP: The On-Site Inspection Playbook

Use this structured table as your primary on-site document. By following this 5-stage protocol, you convert casual observations into clinical data, providing the objective leverage needed for a high-stakes negotiation.

| Phase | Procedure & Required Tools | Decision Thresholds & Leverage |

|---|---|---|

| 0. Prep | Tools:Smartphone (high-res), borescope/mirror, bright flashlight, magnet, small hammer, notepad. | Ensure all tools are functional.Protocol:Never accept seller-provided photos as a substitute for an on-site audit. |

| 1. Photo | Protocol:Wide context → Medium location → Close-up. Capture Title, VIN, Frame, SPID, and Engine Pad. | Timestamp:Immediately upload to cloud/email. An unalterable record is your protection against legal disputes. |

| 2. Identity | Triple-Match Audit:Title ↔ Door/Dash plate ↔ Frame stamping. Check engine pad digits. | Red Flag:Any VIN mismatch requires a written explanation. Engine mismatch = 15–25% valuation adjustment. |

| 3. Structure | Hidden Check:Borescope for cowl plenum, inner fenders, and cab mounts.Hammer/Magnet:Detect filler. | Threshold:>50% shoulder perforation or fresh, inconsistent welds indicate a cab swap or rot.Walk away. |

| 4. Verity | SPID Audit:Cross-check VIN on glovebox label (1967+). Verify at least 2 high-value RPO codes. | Red Flag:Pristine SPID in a weathered interior indicates a reproduction. >1 RPO mismatch = Material provenance issue. |

| 5. Closure | Legal:Secure a signed Disclosure Statement. Request all build sheets, invoices, and prior registrations. | The Exit:If the seller refuses to sign a disclosure or provide documents, do not issue a deposit. |

Sample Written Disclosure Template

If a discrepancy is found, use the following text to secure a written record before leaving the site:

SELLER DISCLOSURE: On [DATE], Buyer inspected VIN(s): Door/Dash [], Frame [], Engine Pad [________]. Discrepancy noted: [Describe mismatch or structural concern]. Seller confirms disclosure of the above and provides the following documents: [List]. Seller Signature: __________________ Date: _______

Negotiation Levers & Valuation Guidance

- Minor Documentation Gap: Request escrowed funds or a price reduction equal to the cost of "re-provenancing" the vehicle (approx. $500–$1,500).

- Engine Non-Matching: Treat as a functional driver/upgrade rather than an investment-grade "Numbers Matching" asset. Adjust price based on local market averages for swaps.

- Frame/VIN Cloning: Demand independent verification or withdraw immediately. These issues effectively bar the truck from premium auctions and significantly limit future appreciation.

Forensic Pro-Tip: Be aware that investment-grade discounts (e.g., 20–30% for a non-matching frame) are based on typical buyer resistance. A truck with a mismatched frame is often barred from top-tier auction houses like Bring a Trailer, effectively capping its future appreciation potential.

Chapter 5: Structural Pathology – Advanced Rust Inspection

In the vintage C10 marketplace, a common veteran's warning holds true: "You aren't buying the paint; you're buying the metal beneath it." Because these trucks were engineered in an era before the widespread adoption of electro-galvanized steel and modern e-coat primers, they are fundamentally susceptible to a specific type of structural decay. To the untrained eye, a fresh coat of high-gloss paint can hide a multitude of sins. To the forensic auditor, however, the goal is to look past the surface and diagnose the incurable pathologies versus the repairable blemishes.

5.1. The Rocker Panel Ecosystem: Diagnosing the Structural Box

The rocker panel is frequently misunderstood as a simple cosmetic strip beneath the door. In reality, it is a sophisticated structural "box" comprised of three distinct layers: the Outer Rocker, the Inner Rocker, and the Floor Support Channel. This ecosystem provides the lateral rigidity for the entire cab. Because this assembly is a hollow chamber, it serves as a primary site for internal oxidation. Water and road salt enter through the cab-corner gaps, settle at the base of the box, and consume the steel from the inside out.

During a field audit, be vigilant for the "Tape Trap"—a common deceptive tactic where rusted-out inner rockers are bridged with aluminum HVAC tape or fiberglass mesh and then masked with a heavy layer of rubberized undercoating. The definitive test is tactile: use the plastic handle of a screwdriver to tap firmly along the backside of the rocker. Healthy steel will produce a clear, metallic ring. If the sound is a dull "thud" or if you hear the distinct crinkling of fiberglass and tape, the structural box has collapsed. Furthermore, inspect the factory drain slots; if they have been filled with body filler or painted over, the rocker is likely a sealed tomb of moisture that will eventually compromise the cab floors.

5.2. Drip Rail Cancer: Identifying the "Pass" Marker

The drip rail, or roof gutter, represents one of the most technically challenging and financially draining repairs on a classic C10. This is the junction where the roof skin is spot-welded to the cab’s skeletal structure. The factory utilized a water-soluble seam sealer in this gutter that, over five decades, becomes brittle and develops microscopic fissures. Through capillary action, moisture is drawn into these cracks, where it remains trapped against raw steel. The resulting oxidation, often called "rust-jacking", physically expands and lifts the roof skin away from the cab frame.

Detecting this "cancer" early is vital for your investment strategy. Look for subtle bubbling paint immediately above the gutter line or vertical orange rust streaks trailing down the A-pillar next to the windshield. Properly rectifying drip rail rot is surgical work; it requires cutting away segments of the roof, grinding out deep-seated scale, and performing precision TIG welding in a highly visible area. For most investors, a truck with advanced drip rail perforation is a definitive "Pass"—the specialized labor costs required to fix it correctly will almost always exceed the truck's potential value appreciation.

5.3. The Bed Floor Reality: Sourcing the Hidden Costs

The bed floor is often the most overlooked component of a C10 purchase, yet it can hide significant restoration costs. Whether the truck is a Stepside with a traditional wood floor or a Fleetside with a steel floor, each has a specific pathology that must be audited before finalizing a price. A weathered wood bed may look like a charming weekend project, but a high-standard restoration can easily exceed $1,500 in parts alone. We recommend reviewing our curated list of C10 parts and accessories to ensure you are sourcing kiln-dried Oak or Ash planks and factory-gauge stainless steel strips.

| Floor Type | Primary Failure Point | Restoration Liability |

|---|---|---|

| Wood (Stepside) | Rotted Cross Sills | High:Replacing sills requires total bed disassembly. |

| Steel (Fleetside) | Front Header Seam | Moderate:Requires extensive spot-weld drilling. |

| Relocated Tank | Improper Crossmembers | Critical:Safety risk if fuel lines are unshielded. |

For steel-floor trucks, the primary focus must be the Front Header Panel—the wall of the bed closest to the cab. Because C10s naturally sit with a slight "nose-down" rake, water pools against this front seam. If the factory drain holes are clogged with decades of silt, this area becomes a permanent moisture trap. Inspecting this seam from the underside of the truck often reveals perforated rot that is invisible from above. Replacing a steel bed floor is "heavy lifting", involving hundreds of spot welds and precision alignment. Always verify if the support "joists" or cross sills are solid; if the wood is rotted, the steel sills beneath are almost certainly compromised, adding another significant layer to your restoration budget.

Cognitive Milestone: You have now moved beneath the "skin" of the C10. You understand that structural integrity is found in the "boxes" and "gutters" of the chassis, not the shine of the paint. By mastering the "Screwdriver Test" and the "Cowl Audit", you have immunized yourself against the most common seller deceptions. In the next chapter, we shift to Mechanical Pathology, analyzing the drivetrain lifeblood and the infamous "Bulkhead Meltdown."

Chapter 6: Mechanical Systems – Drivetrain & Suspension Pathologies

The beauty of the Chevrolet C10 platform lies in its modularity; almost any GM engine from the last 60 years can be made to fit. However, for the investor, this modularity creates a "Frankenstein" risk. A truck that has been modified without a cohesive plan often suffers from mismatched cooling systems, improper gear ratios, and dangerous wiring. Your audit must ensure that the "lifeblood" of the truck—the engine, transmission, and differential—works in harmony.

6.1. The Engine Lineup: Durability vs. Performance

Chevrolet utilized three distinct engine families for the C10. Each possesses a specific "failure mode" that you must identify during your forensic inspection. Whether you are looking for the efficiency of a six-cylinder or the brute force of a Big Block, the following indicators will reveal the engine’s true health.

| Engine Type | Identifying Marker | Forensic "Red Flag" |

|---|---|---|

| Inline Six (292) | Tall Deck / L-Mounts | Cracked Integral Manifolds / Vacuum Leaks. |

| Small Block (350) | "Goodwrench" Sticker | Smog-era 305 Head Swaps (Lower Value). |

| Big Block (454) | Massive Valve Covers | Missing Shroud:Leading to head gasket failure. |

- The "Stovebolt" Inline Sixes:The 292ci is the "Torque Monster" of the family. Inspect the exhaust manifold carefully; because the intake and exhaust are often bolted together in an "integral" design on later models, a heat-cycle crack can lead to a persistent vacuum leak that is nearly impossible to tune out without a full manifold replacement.

- The Small Block Chevy (SBC):The 350ci is the gold standard for parts availability. Look for the silver "Goodwrench" sticker on the valve covers; this indicates a later GM Crate Engine. While this eliminates "numbers-matching" status, it is a significant plus for reliability, as these blocks typically feature better metallurgy than a high-mileage factory 1970 unit. Conversely, avoid the 305ci "smog-compromise" engines unless the truck is priced significantly lower to accommodate an inevitable swap.

- The Big Block (396, 402, 454):These engines generate immense thermal loads. Your primary forensic action is to inspect theradiator shroud. A Big Block C10 without a factory-style shroud will overheat in less than 10 minutes of stop-and-go traffic. If the shroud is missing, immediately check the oil for a "milky" texture, a definitive sign of an overheated head gasket.

6.2. Transmission Considerations: The "Driveability" Factor

The transmission dictates the "soul" of the truck. You must determine if the vehicle offers a "vintage utility" feel or a "modern cruise" experience. The most desirable upgrade in the modern market is the 700R4 Overdrive automatic. Introduced in the early 80s, this transmission is a significant "ROI Multiplier." If a 1967–1972 truck has been retrofitted with a 700R4, it adds an immediate $1,500–$2,000 in value, as it allows the engine to drop from a screaming 3,500 RPM to a calm 2,200 RPM at highway speeds.

If the truck retains its original manual transmission, identify it by the shifter. The SM465 features a massive, curved lever and a "Granny Low" first gear designed for pulling stumps. While virtually indestructible, it drives like a tractor. For a daily-driver enthusiast, this transmission is often the first thing they regret once the novelty of the "old truck feel" wears off.

6.3. Differential Gearing: The "Hidden" Performance Killer

Many C10s were originally ordered as "Utility" vehicles, meaning they were equipped with "short" gears (3.73 or 4.11) designed for hauling heavy loads at 45 MPH. Without an overdrive transmission, these gears make the truck nearly unusable on modern interstates. If the SPID label is missing, you must perform the Jack-Stand Test to verify the ratio manually.

The Math of the Audit: Jack up the rear tires and place the truck on stands. Mark a line on the tire and the driveshaft. Rotate the tire exactly one full rotation. If the driveshaft spins ~3 times, you have 3.08 gears (Highway Friendly). If it spins ~4 times, you have 4.11 gears (The Stump Puller). Understanding this ratio allows you to predict whether the truck will be a comfortable cruiser or an engine-straining liability at highway speeds.

Cognitive Milestone: You have now mastered the drivetrain investigation. You know that a 292 Six is a torque king, that a missing radiator shroud on a Big Block is a deal-breaker, and how to "read" your gear ratio without specialized tools. In the next chapter, we move to the "nervous system" of the truck: The Electrical and Interior Systems, where we investigate the infamous "Bulkhead Connector Meltdown."

Chapter 7: Electrical and Interior Systems – The Nervous System Audit

The transition from a "project" to a "reliable driver" is almost always won or lost in the wiring. General Motors’ electrical engineering in the 1960s and 70s was adequate for the era, but it did not account for 50 years of terminal oxidation and the added load of modern accessories. A forensic audit of the dashboard and firewall will reveal if the truck is a "plug-and-play" asset or a ticking fire hazard.

7.1. The Bulkhead Connector Meltdown: A Critical Safety Failure

From 1960 through 1987, General Motors utilized a "Bulkhead Connector"—a multi-pin plastic block located on the engine-side firewall—to bridge the exterior wiring with the cabin harness. This single component is the most common point of total electrical failure. Over decades, the tin-plated brass terminals within the connector oxidize, creating electrical resistance. This resistance generates heat, and since nearly all cabin power (including high-draw headlights) is routed through this junction, the plastic housing eventually melts or "caramelizes."

| Symptom | Probable Cause | Action Required |

|---|---|---|

| Flickering Headlights | Bulkhead Resistance | Perform "One-Bolt" Inspection. |

| Erratic Fuel Gauge | PCB Ground Failure | Replace Instrument Circuit Film. |

| Burning Plastic Smell | Shorted Main Feed | STOP:Full Harness Audit. |

The One-Bolt Audit: To verify safety, use a 3/8" socket to remove the center bolt on the firewall wiring block and pull the harness away. If you see black soot, green corrosion, or melted plastic around the large red power wires, the harness is compromised. A full replacement from high-end suppliers costs $800–$1,200 in parts alone. For detailed troubleshooting steps on this and other electrical issues, visit our C10 repair and maintenance hub to account for the significant labor costs that must be deducted from the purchase price.

7.2. Interior Plastic Degradation: The UV Stability Crisis

The 1973–1987 "Squarebody" generation marked a significant shift toward molded plastics. Unfortunately, the chemical stabilizers used during this era had virtually zero resistance to long-term UV exposure. Original dash pads are notorious for "canyons"—deep cracks caused by the internal foam expanding while the vinyl skin shrinks. Be wary of "Dash Caps"—cheap plastic overlays glued over the damage. A hollow "clack" sound when tapping the dash indicates a cap; a proper restoration requires a full urethane replacement, costing $400+ and hours of dashboard disassembly.

7.3. Instrument Cluster PCBs: The Grounding Failure

Behind the gauges lies a flexible, copper-clad plastic film—the Printed Circuit Board (PCB). This is the most fragile component of the interior. Over time, heat causes the copper traces to delaminate from the film, leading to "ghost" electrical issues where turning on a blinker might cause the fuel gauge to move. Perform the 3 O’Clock Test: turn the ignition to "On" and watch the fuel gauge. If it "pegs" immediately past the Full mark to the 3 o'clock position, the ground circuit on the PCB is broken. While the part is inexpensive, the labor to dismantle the cluster is significant and serves as a key negotiation leverage point.

Cognitive Milestone: You have now completed the full "Forensic Audit" of the Chevrolet C10. You can now see through fresh paint to detect cowl rot, hear the difference in a failing torsion bar, and diagnose fire hazards at the bulkhead connector. You have transitioned from a buyer to a specialist. Your final step is to apply the Strategic Market Checklist to ensure your purchase becomes the cornerstone of a winning automotive portfolio.

Chapter 8: Strategic Sourcing and the Permanent Market Outlook

The marketplace for the Chevrolet C10 has matured from a speculative hobby into a discerning asset class. Investors and enthusiasts alike have moved past the "blind buying" era, replacing it with a "quality-first" philosophy. Understanding the delta between a "Catalog Build" (trucks assembled from generic reproduction parts) and a "Forensic Restoration" (vehicles retaining original structural integrity) is the primary factor in long-term value retention. As the supply of original, rust-free steel continues to diminish, the strategic buyer must prioritize structural "completeness" over a low entry price.

8.1. The Investment Matrix: Navigating the Quality Gap

In the classic truck economy, there is a consistent "Flight to Quality." While the entry-level floor for "barn find" projects remains accessible, the financial barrier to completion is higher than ever. A project truck purchased at a significant discount that requires total metal fabrication is often a greater financial liability than a premium-priced, turn-key vehicle. Buyers increasingly prefer to pay a premium for a finished product with a documented "frame-off" history rather than navigating the unpredictable labor timelines and escalating costs of a multi-year restoration.

The Logistics of Restoration: High-quality stamped sheet metal—specifically cab floors and bed sides—is subject to global supply chain fluctuations. Because the majority of these heavy steel panels are manufactured overseas, shipping and logistics costs often outweigh the price of the part itself. For the strategic restorer, the most efficient path is to source a truck with the most original "factory tin" possible, as even the best reproduction panels rarely match the fit and gauge of original GM steel.

8.2. The "Unobtanium" Parts List: The Scarcity Audit

In a professional restoration, "missing" parts are often more expensive and harder to solve than "broken" ones. Before finalizing a purchase, you must verify the presence of these high-scarcity items, as their absence indicates a multi-month search and a significantly higher final budget:

- 1967-Specific Hardware:Interior knobs, window cranks, and bezels were "one-year-only" designs. Original, un-pitted sets are increasingly rare and often command a 300% premium over 1968–1972 equivalents.

- Factory Bucket Seat Brackets (1967–1972):Converting a bench seat to buckets safely requires factory-contoured steel brackets. These are rarely found in catalogs and must be scavenged from original donor trucks.

- Original Big Block Cooling Components:Large plastic fan shrouds for 396 and 454 engines are prone to heat-cracking and brittle failure. A truck missing this shroud often suggests a history of cooling system neglect.

- 1960–1962 Torsion Components:These are the rarest suspension parts in the C10 lineage. If a control arm is bent or rusted through on these early frames, the vehicle is effectively sidelined until a donor chassis can be located.

8.3. The Master Audit: A Final Strategic Checklist

Before you sign the title, perform this 5-point forensic finalization. This is the synthesis of every technical chapter provided in this guide, designed to ensure your investment is a secure legacy.

| Audit Point | Requirement | Failure Implication |

|---|---|---|

| Identity | Triple-Match (Frame/Plate/Title) | Legal Liability:Voids investment-grade status. |

| Cowl Plenum | Clear Drains (10-second flush) | Hidden Rot:Expensive firewall reconstruction. |

| Structure | Inner Rocker "Tap Test" | The Tape Trap:Collapsed structural rigidity. |

| Electrical | Clean Bulkhead Terminals | Fire Hazard:Immediate harness replacement. |

| Chassis | No "Tail Wag" on Lane Change | Suspension Fatigue:Failed bushings or rivets. |

Cognitive Journey Summary: From Buyer to Steward

By adhering to this technical manual, you have transitioned from an emotional buyer to a forensic steward of automotive history. You now possess the specialized knowledge to navigate the global C10 marketplace with clinical precision. The Chevrolet C10 is more than a vehicle; it is a cultural icon. When you secure a truck with a straight frame, a verified VIN, and a solid cowl, you are not just purchasing a pickup—you are preserving a piece of the American road. Be sure to bookmark this Ultimate Chevrolet C10 Buyer's Guide as your primary reference for future on-site inspections.

Technical Inspection & Safety Notice: This guide provides a forensic framework for identification and investment analysis. However, it is not a substitute for a professional mechanical evaluation. All safety-critical components—including chassis integrity, steering kinematics, and electrical systems—must be verified by a certified structural technician before the vehicle is deemed roadworthy.

- LMC Truck: 1960-64 Chevrolet Serial Identification Number Official Manual

- LMC Truck: 1973-80 Vehicle ID Number (VIN) & Chassis Identification

- GMC Paul's: 1967-1972 Chevrolet VIN Number Codes & Factory Identification

- USA1 Industries: 1981-1987 Chevrolet & GMC Truck VIN Decoding Guide

- JEGS: GM & Chevy Truck VIN Decoder Technical Chart

- Hagerty Media: The Definitive 1967–72 Chevrolet C/K Pickup Buyer's Guide

- CJ Pony Parts: Expert Guide to Buying a Classic Chevy C10

- Classic Industries: 1960-1972 Chevy Truck Model Years Identification Guide

- Speedway Motors: 67-72 C10 Rust Repair - Cab Floor & Rocker Replacement Tech Talk

- Diesel Power Products: Diagnosing & Replacing Steering Gear Box Frame Issues

- DecodeRPO: GM Regular Production Option (RPO) Master Database

- Houston Engines: GM RPO & SPID Sticker Guide for Engines & Transmissions

- Hagerty Valuation: Historical Price Trends for Chevrolet C10 (All Eras)

- Cox Automotive: April 2025 ATP Report - Tariffs and Market Price Impacts

- AACA Forums: 1960-1962 Chevrolet/GMC Technical Discussion

- C10 Community (Reddit): Bulkhead Connector Removal & Safety Audit Discussion